Design and Numerical Validation of a Low-cost and Reusable Resonant Igniter using Modern Additive Manufacturing Methods for Use in Rocket Propulsion

£5.00

E. Aoubala (2022), JBIS, 75, pp.3-8

Refcode: 2022.75.003

DOI: n/a

Abstract:

Recent developments in the ignition systems used to ignite bi-propellant rocket engines have led to ignition concepts that were previously considered only theoretical to be re-examined as manufacturing technologies have improved to make them more viable. Among them are resonance igniters, which provide a lucrative alternative to traditional igniters in that they do not require any electrical input and are based upon shockwave vibrations due to their unique geometries. This provides the opportunity for use of non-hypergolic propellants procedurally like hypergolic with high reliability. The most successful previous attempt had used the additive manufacturing method of ‘Selective Laser Manufacturing’ (SLM) by the Firefly group, which was shown to solve issues relating to cooling and durability. However, issues with thermal hot spots and material ablation were found, limiting the overall reusability of the proposed igniter. This study aims to use the newly developed technology of Binder Jetting Additive Manufacture, which has been shown to have much higher flexibility in geometric design as compared with SLM, such that more complex geometrical optimization with alternative cooling methods can be applied to allow for reusable operation of the resonant igniter, with a long operational life and minimal servicing. An optimization Digital twin program was additionally developed to optimize the regenerative coolant channels and film cooling percentages with the constraints applied through the list of requirements.

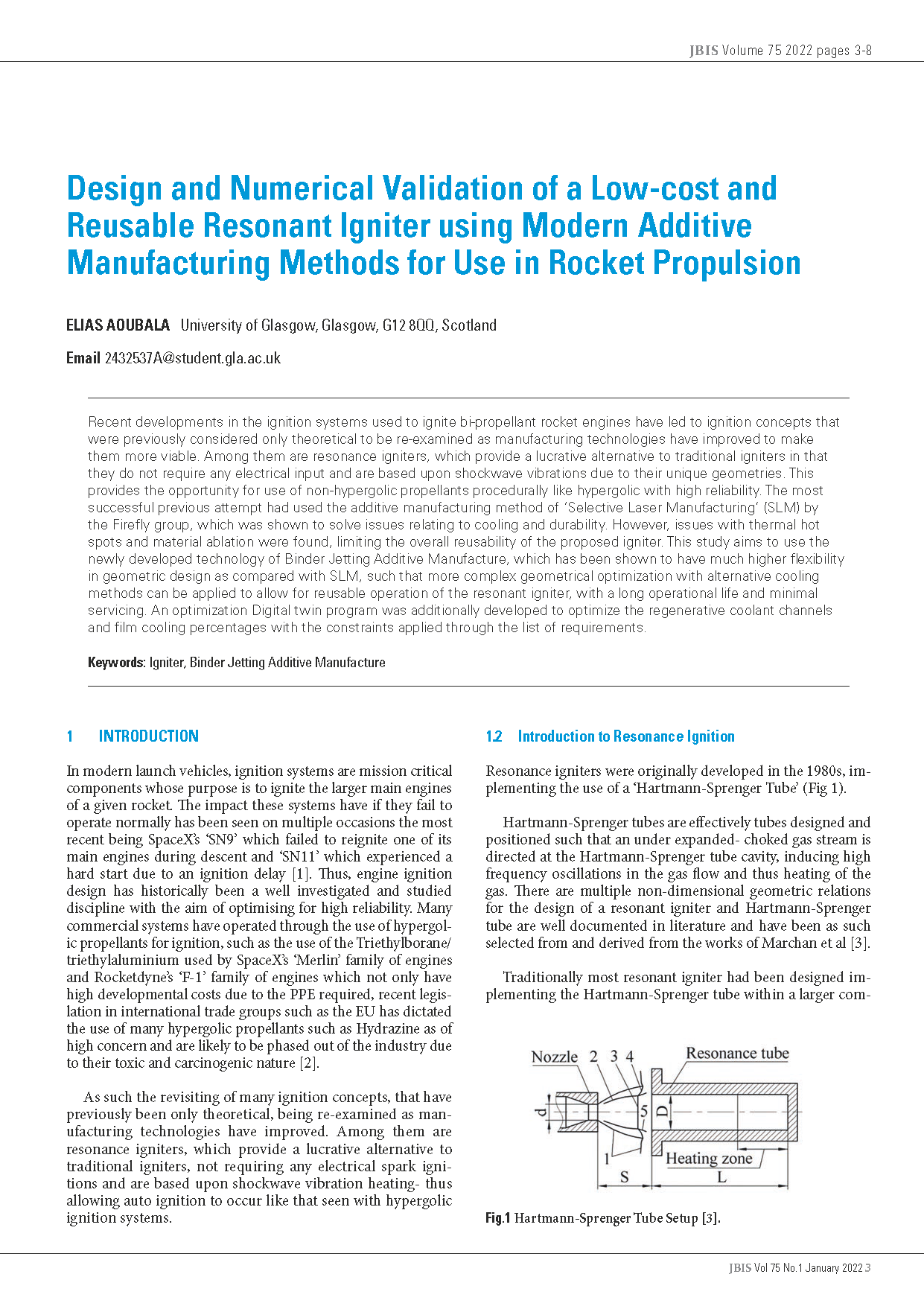

Keywords: Igniter, Binder Jetting Additive Manufacture